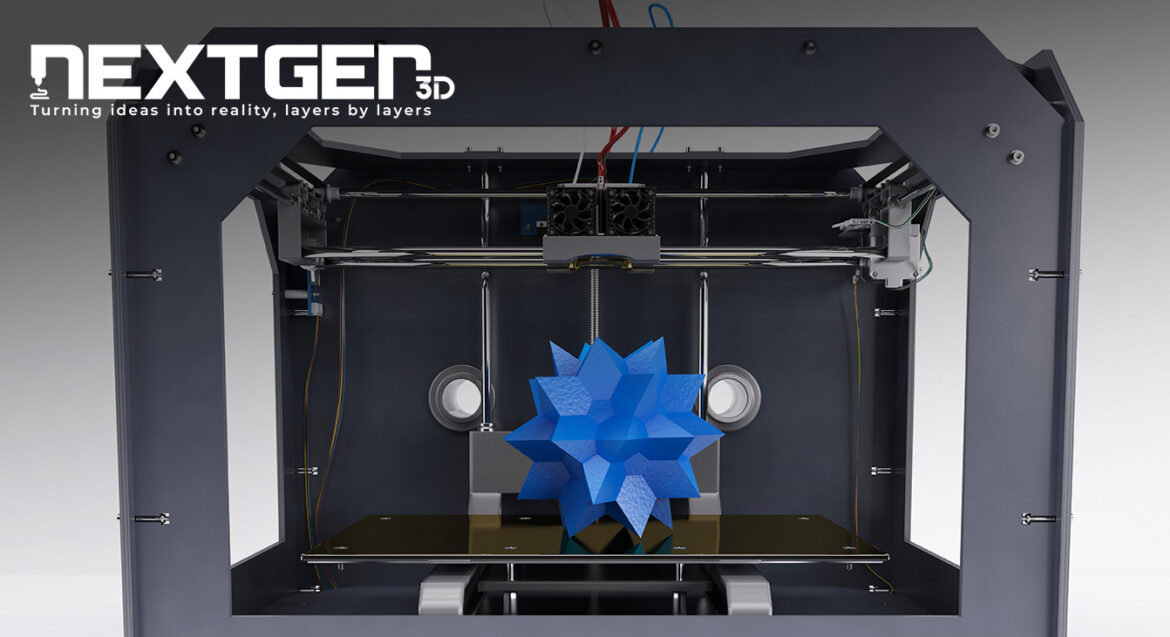

3D Printing Innovations As we approach 2025, advancements in 3D printing technology are driving transformative changes across industries, including manufacturing, healthcare, and construction. In Oman, NextGen3D is reshaping the industry with continuous developments present unique opportunities to modernize industries, enhance production efficiency, and support sustainable practices.

1. Multi-Material and Multi-Color Printing

Historically, 3D printing has been limited to single-material outputs, which constrained the complexity and functionality of printed objects. However, recent advancements are enabling printers to handle multiple materials and colors simultaneously. This capability allows for the creation of complex, multi-component objects in a single print cycle, significantly reducing assembly time and expanding design possibilities. For example, the integration of conductive and structural materials within a single print enables the production of functional electronic devices directly from the printer. This innovation is particularly promising for industries like electronics and automotive manufacturing, where diverse material properties are essential for functionality.

2. High-Throughput and Large-Scale Printing

The development of high-speed 3D printers is making additive manufacturing more viable for mass production. These printers can produce large volumes of parts in shorter timeframes, while large-scale 3D printers are constructing sizable structures, such as housing components and industrial equipment. Such advancements are especially relevant in the construction and automotive industries, where there is a high demand for large, durable components. Large-scale 3D printing also offers a sustainable alternative to traditional construction methods, as it uses materials efficiently and allows for on-demand production, which can reduce waste and lower costs.

3. Integration of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are increasingly being integrated into 3D printing processes, enhancing both precision and efficiency. AI-driven systems enable real-time monitoring and adjustment of printing parameters, improving print quality and reducing material waste. Additionally, AI-powered design tools allow for the creation of complex geometries previously unattainable, opening new possibilities in product development. These advancements support the growing demand for intricate and customized products in sectors such as aerospace and healthcare, where precision and performance are paramount.

4. Sustainable and Recycled Materials

With a growing emphasis on environmental responsibility, the 3D printing industry is innovating in sustainable materials. New biodegradable and recyclable materials are emerging, enabling manufacturers to reduce their environmental footprint. For instance, initiatives to repurpose waste materials, such as discarded fishing nets, into high-quality nylon filament for 3D printing are addressing ecological concerns while offering cost-effective solutions. These materials are increasingly being used in sectors like consumer goods and packaging, where sustainability is becoming a core value.

5. Medical and Healthcare Applications

The healthcare industry continues to benefit from advancements in 3D printing, especially in the production of patient-specific medical devices. Innovations in biocompatible materials and precision printing techniques are facilitating the creation of implants, prosthetics, and even bioprinted tissues tailored to individual patients. These applications are enhancing personalized medicine and improving patient outcomes by offering solutions that closely match patients’ anatomical requirements. In Oman, where healthcare services are advancing rapidly, the adoption of 3D printing could support more effective and tailored medical treatments.

6. Enhanced Software and Design Tools

New software tools are simplifying the 3D printing design process, making it more accessible to a broader audience, including small businesses and educational institutions. User-friendly interfaces and advanced features for complex modeling and simulation streamline the transition from concept to printed object. These tools empower designers and engineers to create highly customized and optimized parts, enhancing creativity and productivity across industries. For Oman’s educational sector, these tools can provide students with early exposure to cutting-edge technology, preparing them for future careers in engineering, design, and technology.

Implications for Oman

These advancements in 3D Printing Innovations technology have significant implications for Oman, offering pathways to strengthen its industrial and manufacturing sectors. Multi-material and large-scale printing capabilities can enhance local production, reducing dependency on imports and supporting economic growth. The integration of AI and sustainable practices aligns with global trends toward smart manufacturing and environmental responsibility. Moreover, advancements in medical applications can greatly benefit healthcare services in Oman, providing customized solutions for patients and contributing to improved health outcomes.

The 3D Printing Innovations set for 2025 promise to redefine various sectors by enhancing production efficiency, supporting sustainability, and expanding the scope of applications. As Oman embraces these developments, it can leverage 3D printing to drive industrial growth, improve healthcare services, and foster a sustainable future. By staying at the forefront of technological progress, The companies like NextGen3D are playing vital role in reshaping the economy and Oman positions itself to benefit from the full potential of 3D printing, enhancing the quality of life for its citizens and contributing to a more innovative and resilient economy.