Table of Contents

In an age where environmental responsibility is no longer optional, NextGen3D is setting a standard for Sustainable 3D Printing in Oman Through an eco-conscious approach that spans material selection, energy-efficient production, waste reduction, and local manufacturing, NextGen3D is minimizing its environmental impact while enhancing efficiency. As sustainability becomes a central pillar in modern production, NextGen3D exemplifies how advanced technology and environmental stewardship can work hand in hand.

Eco-Friendly Materials for a Greener Future

A foundational aspect of NextGen3D’s commitment to sustainability is its choice of materials. The company prioritizes biodegradable and recyclable options that have minimal environmental impact. For example, it incorporates plant-based bioplastics like PLA (polylactic acid), a renewable and lower-emission alternative to petroleum-based plastics. PLA is derived from cornstarch and is biodegradable, making it an ideal choice for reducing waste and supporting a circular economy. By selecting such materials, NextGen3D not only reduces its ecological footprint but also sets a precedent for responsible material sourcing in Oman’s manufacturing landscape.

Energy-Efficient Production Techniques

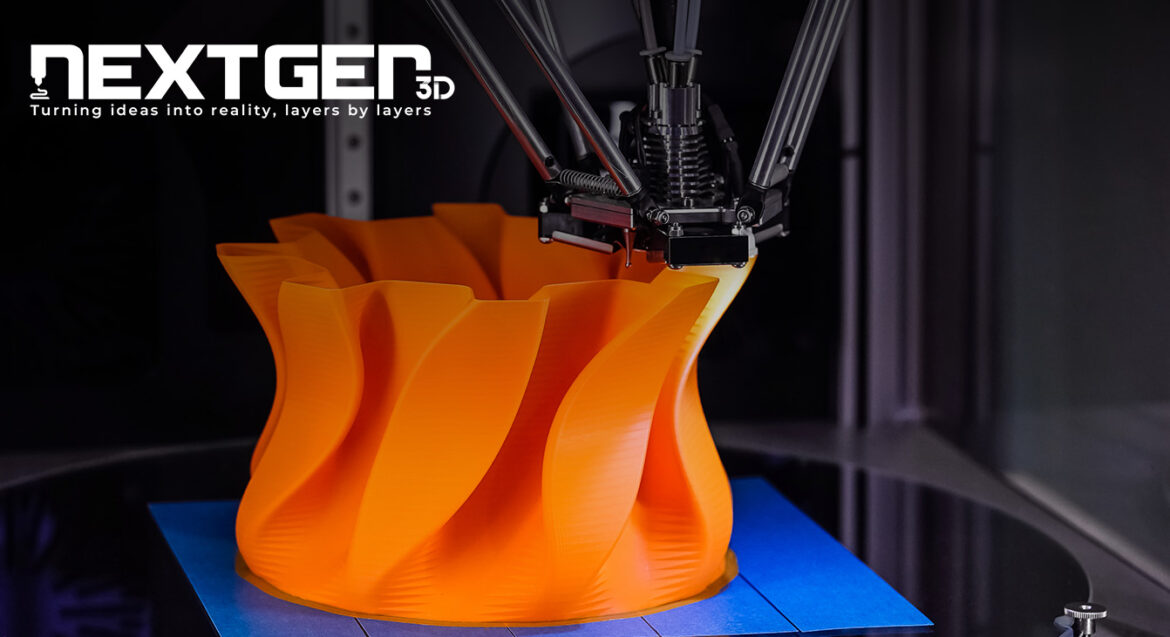

3D printing, by nature, is more resource-efficient than traditional subtractive manufacturing. NextGen3D capitalizes on this advantage by employing advanced energy-saving technologies across its production processes. Additive manufacturing builds products layer by layer, using only the material required for each part and thus reducing waste. NextGen3D goes a step further by optimizing machine usage and incorporating low-energy printing methods. This approach reduces the overall carbon footprint of each production cycle, ensuring that each project aligns with the company’s sustainability goals.

Reducing Waste Through Precision and Recycling

Traditional manufacturing processes are known for generating substantial waste, especially in sectors that require high precision. Additive manufacturing, however, uses only the necessary amount of material, leading to significantly less waste. NextGen3D leverages this advantage by not only using precise production methods but also implementing recycling initiatives. For any leftover or discarded materials, the company has established processes to repurpose them within its operations. This commitment to recycling minimizes resource consumption and aligns with sustainable manufacturing principles, further shrinking NextGen3D’s environmental footprint.

Localized Production to Reduce Emissions

One of the unique contributions NextGen3D brings to Oman’s 3D printing industry is its emphasis on localized production. Traditionally, the manufacturing sector relies on complex global supply chains, which contribute to carbon emissions from transportation. By focusing on local production, NextGen3D reduces the need for long-distance shipping, thereby minimizing the associated environmental impact. This approach not only supports Oman’s local economy but also allows NextGen3D to maintain a streamlined, eco-conscious supply chain. By cutting down on transportation-related emissions, the company exemplifies how local manufacturing can be both sustainable and efficient.

Continuous Improvement in Sustainability

As a forward-thinking company, NextGen3D is committed to continuously evolving its sustainability practices. The company invests in research and development to explore new materials and production techniques that further enhance its environmental performance. This dedication to improvement ensures that NextGen3D remains aligned with Oman’s vision for an innovative, sustainable manufacturing sector. By staying at the forefront of sustainable advancements, NextGen3D not only meets current environmental standards but also positions itself to adapt to future sustainability requirements.

Setting Standard for Sustainable Manufacturing in Oman

Through its focus on eco-friendly materials, energy-efficient processes, waste reduction, and localized manufacturing, NextGen3D has become a model of sustainable 3D printing practices in Oman. As the country’s manufacturing sector continues to grow, NextGen3D’s approach serves as a benchmark, illustrating the importance of environmental responsibility in modern production. The company’s commitment to refining its sustainable practices is not only contributing to a greener Oman but also setting a standard that other businesses may aspire to follow.

In an era where environmental sustainability is essential, NextGen3D’s practices in sustainable 3D printing reflect a profound dedication to eco-friendly innovation. As the company advances in sustainable technology, it demonstrates how environmental responsibility can drive business success, positioning NextGen3D as a leader in Oman’s manufacturing sector and a catalyst for sustainable industrial growth in the region. By aligning advanced manufacturing capabilities with eco-conscious practices, NextGen3D exemplifies the future of sustainable industry in Oman.